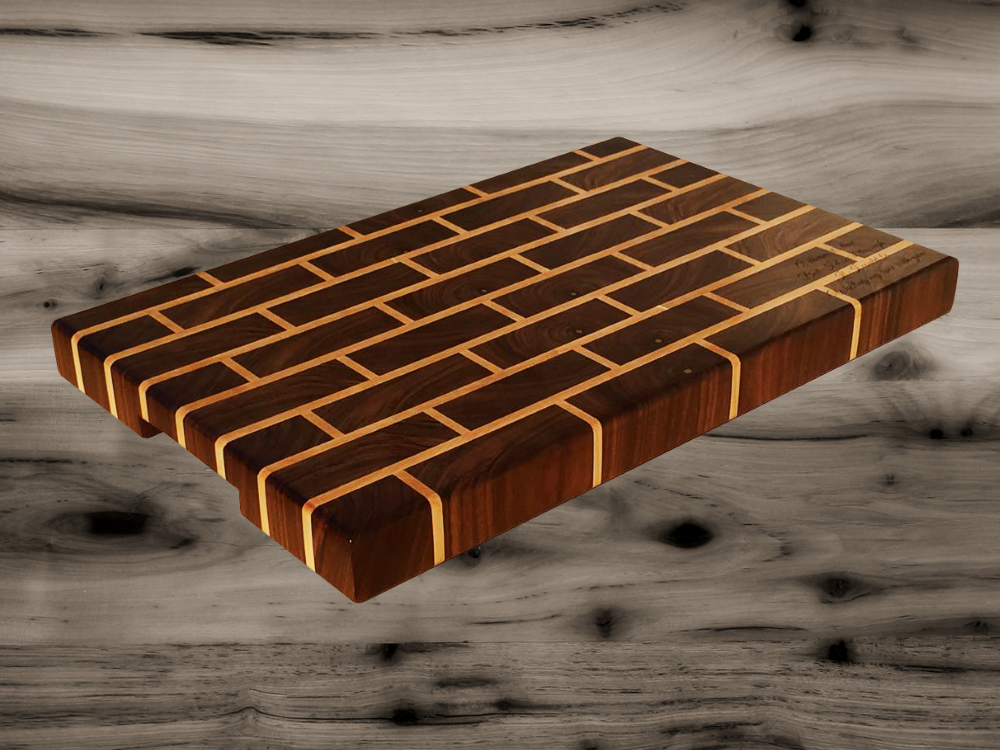

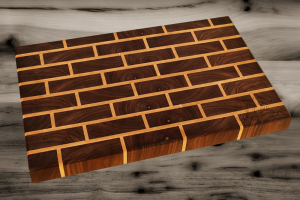

***ABOUT THIS PRODUCT***

Dimensions: 450 x 300 x 38mm (18″ x 12″ x 1.5″)

Made of Black Walnut & Hard Maple

Includes:

End Grain Cutting Board – Proper Care & Maintenance (PDF)

More about NicheBoards – Handmade End Grain Cutting Boards

Our handmade end grain cutting boards are made from hardwoods perfectly suited for use in cutting boards. The woods most commonly used in our cutting boards, Hard Maple and American Walnut, are tight grained, hard and not oily. This together with the use of the end grain rather than the face grain,ensures a durable surface, which with proper care, will give you and your family years of service. Our cutting boards are custom made to various sizes and different pattern layouts are available. Small recesses cut into the sides make it easier to handle when sitting on a flat surface. The glue used in the joining process is food safe and approved by the FDA. All our boards are initially treated with a mixture of mineral oil and beeswax; a food safe finish. Thereafter each board is treated once a day for seven days with mineral oil to ensure a water resistant finish. As a general rule, cutting boards should be treated, once a day for a week, then once a week for a month, once a month for a year and thereafter once a year. Together with your board, you will receive a small bottle of mineral oil, which can be applied easily at the appropriate times using a soft cloth. Since our boards are end grain, it’s a bit more forgiving in terms of grain structure than a face grain board would be. This means that woods like Mahogany and Cherry can be used as alternatives to Maple and Walnut. Purple Heart cutting boards are also made on request.

Why end grain?

End grain cutting boards offer a much harder and thus more durable cutting surface than regular face- or edge grain cutting boards. These boards offer a truly resistant cutting surface while being kind to the knife blade’s sharp edge. In end grain boards, individual boards of wood are arranged so that the grain runs vertically. This construction means the cutting surface is made up of the ends of individual pieces of hardwood. When cutting on end grain surfaces, the knife blade runs between the wood fibers instead of crushing against them as is the case when cutting on regular (face- or edge grain) cutting boards. This accounts for the ‘self-healing’ aspect of the end grain surface and the main reason professional chefs rely on and use end grain cutting boards: Sharp knives stay sharper for longer.

In conclusion:

When buying an end grain cutting board you have a surface that is kind to your favorite knife blades while being super hard and durable thus ensuring a smooth beautiful surface for years to come.